Thin Film Deposition System Standard Configuration

The CCS CA-50/CA-150’s Standard Configuration includes the following components. Custom Options are also available.

Deposition Controller

The Telemark 861 electron beam source quartz crystal (QCM) deposition controller with modern color LCD touch screen interface and capability for I/O upgrades and additional sensor heads makes this tool excellent deposition systems. The unit contains an extensive material library and user definable materials. Storage capability of 99 processes of up to 999 layers each.

Features

- High frequency internal reference oscillator provides <0.01A resolution for aluminum

- Operates with 5 MHz or 6 MHz crystals

- All new innovative crystal oscillator design for outstanding stability and noise immunity

- Extensive materials library, also allowing for user definable materials

- Color LCD touch screen for graphical and numerical display of primary real-time process data, providing an intuitive and user friendly operator interface

- Touch screen capabilities: In-process parameter modification, Process and Layer editor, I/O status and control

- Real time graphical display of: Power v/s time, Rate v/s time, Thickness v/s time, Rate deviation v/s time

- All system, film and setup files may be saved via a front panel USB port, as well as uploaded to instrument

- Can accommodate up to 99 processes of 999 layers each

- Standard unit has 2 crystal sensor inputs and 2 isolated rate control analog output drivers, expandable to 4 each.

Specifications

| Crystal Frequency: | 5 or 6 MHz |

| Resolution: | <0.02Hz (<0.01A for Al @ 6MHz) |

| Accuracy: | +/- 0.5% thickness |

| Thickness Display: | 0.000 – 999.9 kÅ |

| Power Display: | 0.0 – 99.9 % |

| Rate Display: | 0.0 – 999 Å/s |

| Measurement Update: | 10 per second |

| Inputs: | 8 standard (32 max.) optically isolated, active (12 to 24V DC), or passive (contact closure) |

| Outputs: | 8 standard (32 max.) relay contacts, max 2A, 50 DC |

| Analog Outputs: | 2.5, 5 or 10 volts @ 20 ma. 0.002% resolution |

| Power Input: | 90-264 VAC, 47-63 Hz |

Vacuum Gauge Controllers

390 Micro-Ion ATM Modules

The Granville-Phillips® Micro-Ion® ATM module combines proven Micro-Ion ionization gauge technology with a miniature Conductron® heat loss sensor and two Piezo resistive sensors to provide accurate, continuous pressure measurement from high vacuum to atmosphere.

- Continuous pressure measurement from high vacuum to atmosphere

- Dual ionization gauge filaments increase equipment uptime

- Optional setpoint relays for process control

- Analog, RS-485 or DeviceNet output available

- Optional graphics LCD display

Granville-Phillips 275 Mini-Convectron® Modules

Combines the industry standard Convectron gauge with electronics in a compact modular design.

- Measures from atmosphere to 1×10-3 Torr (1×10-1 Pa)

- Basic models come with one or two setpoint relays, enabling you to use them as a pressure switch

- Easy-to-read three-digit displays allows pressure readings as point-of-use

- All-metal package is virtually immune to RF interference

Power Supply

- Simultaneous operation of up to 3 sources.

- Robust overrated tetrode tube for superior instantatneous arc-down recovery.

- < 0.5% voltage regulation.

- Adjustable constant voltage maintains stable beam position.

- Constant emission current regulation < 1%.

- Full remote operation from PLC for both High Voltage and Source

- Handheld joystick sweep control

- Optional programmable sweep

- Air cooled

E-gun

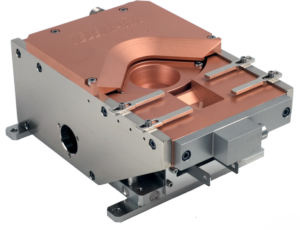

Telemark Multi-pocket E Beam sources

- ROTATABLE HEARTH IS REMOVABLE FOR EASY CLEANING OR CHANGING OF CRUCIBLES

- 270° beam deflection (Hidden Filament)

- Proprietary, patented water cooling design means longer crucible life and more consistent evaporation of material

- Rugged, reliable construction

- Designed for ease of use and maintainability

- Permanent magnet for primary beam positioning to provide improved control of evaporation process

- Durable emitter assembly with unique design for increased filament life and simple maintenance

- Plug-in emitter assembly for easy filament replacement

- Side crucible rotation drive